Description

Below are the training objectives for Lean Six Sigma Yellow Belt Level (LSSYB):

- The Yellow Belt participants will have more in-depth knowledge of Lean and Six Sigma, and each of the five phases that are to be applied in practical terms.

- This course is designed to provide a broad understanding of the Lean and Six Sigma improvement methodology, concepts, and language, along with a complete toolbox of basic process improvement methods.

- The Six Sigma Yellow Belt course is designed to enhance technical problem-solving skills. Instruction is application focused, therefore requiring all participants to successfully support existing or new Lean and Six Sigma projects.

- The Yellow Belt upon completion of this training will participate as a core team member or subject matter expert on a project or projects together with the supervisors/managers.

You can take a Quiz to determine which Six Sigma course you are best suited for : Six Sigma Programme Eligibility Quiz

Included in this training

- LSSYB Internal certification

- Examination

- Assignment

- Coach for the assignment

- Full Materials in PDF

- LSSYB eBook

- LSSYB project workbooks

- LSSYB templates

Examination, Assignment and Certification

We will administer an examination for the participants upon completion of their training. The examination consists of the following (online post training completion):

LSS YELLOW Belt Level (Internal Exam)

Exam Type : Multiple Choice Questions

No. of Questions : 15 Questions

Examination : Open Book Examination

Passing Rate : 70% and above

Duration of Exam : 30 minutes

Location of Exam : Online using Google Forms

Minitab and Project Templates during Yellow Belt Lean Six Sigma Training

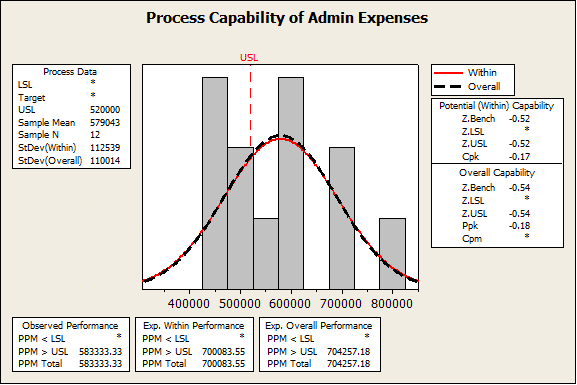

Where applicable, during the training course, our consultants will provide the participants with training on how to analyse Quality data using the Minitab software which is widely used by Lean Six Sigma practitioners.

Example of Minitab Software:

OUR CONSULTANTS WILL ALSO PROVIDE CANDIDATES WITH USEFUL EXCEL QUALITY TEMPLATES AND TOOLS

For full certification, participants will be given a short assignment to be completed within 21 days of completing the examination above. Details of the assignment will be provided by the trainer.

Training Content and Timing Plan

Phase 1 (Online 9am – 1pm)

- Overview of Six Sigma – DMAIC & Lean PDCA

- DMAIC vs. Other Approaches, 7 Wastes TIMWOOD

- Cost of Poor Quality (COPQ)

- Understanding Project Charters and Prioritisation Tools

Phase 2 (Online 9am – 1pm)

- Root Cause Analysis (RCA) Tools

- Data Collection Techniques

- Basic Lean Enterprise, Lean Ways of Working

- Workshop Sessions & Video Analysis

- Basic Statistics and Graphical Analysis using Minitab Software

Phase 3 (Online 9am – 1pm)

- Fishbone Diagrams with creating C&E Matrix

- Process Flow Charts / SwimLane Diagrams

- Understanding Value Added (VA) and Non-Value-Added Activities

- (NVA)

- Types of Statistical Analysis (Quantitative & Qualitative)

- Workshop Sessions – 7QC Tools, RCA Tools

- Generating Improvement Ideas

Phase 4 (Online 9am – 1pm)

- Poke – Yoke (Mistake Proofing) with Lean Tools

- Running Pilot Six Sigma Programmes

- Solutions Implementation Plan

- Understanding Statistical Process Control

- Establishing Control Plans

- SOP & Documentation

- Final Review of Yellow Belt Session

Reviews

There are no reviews yet.