Picture yourself waking up each morning with a sense of dread, knowing a mountain of tasks awaits you. From A to Z, it feels like an endless list of to-dos looming over your head.

Well, you might already be experiencing it.

Juggling multiple tasks can be challenging enough, but when one lacks proper organization or management, tasks can quickly pile up, leaving us feeling utterly overwhelmed, stressed, and less productive. Without a proper way to prioritize and manage tasks, we find ourselves struggling to identify which tasks are more important or more urgent to do. Thus, this may cause one to experience an overpowering sense of anxiety, leading to a lack of focus and procrastination. As a result, tasks pile up, deadlines overdue, important information overlooked, mistakes made, and ultimately, KPIs not achieved.

Overall, it is apparent that everyone needs a proper system or management skills to not only safeguard their mental and emotional health but also be successful in their career.

That’s where Kanban comes into play.

WHAT IS KANBAN?

To put it simply, Kanban is a simple but highly effective task management tool, under the Agile methodology for project management and Lean Manufacturing, designed to help individuals visualize, organize, keep track, and optimize their workflow [1-3, 7, 12]. Essentially, it is used to manage multiple deliverables across a team to prevent feeling overwhelmed and burnout.

Additionally, Kanban helps in managing workloads to prevent the formation of bottlenecks by monitoring the number of tasks, the status, and the cruciality of each task. Therefore, if issues emerge, they can be quickly identified and addressed [4].

Kanban is presented in the form of a “Kanban Board”. Kanban originates from Japan and in Japanese, “Kan” means “Visual” and “Ban” means “Card” which translates to “Signboard” [5, 6]. Hence, Kanban Board.

KANBAN BOARD

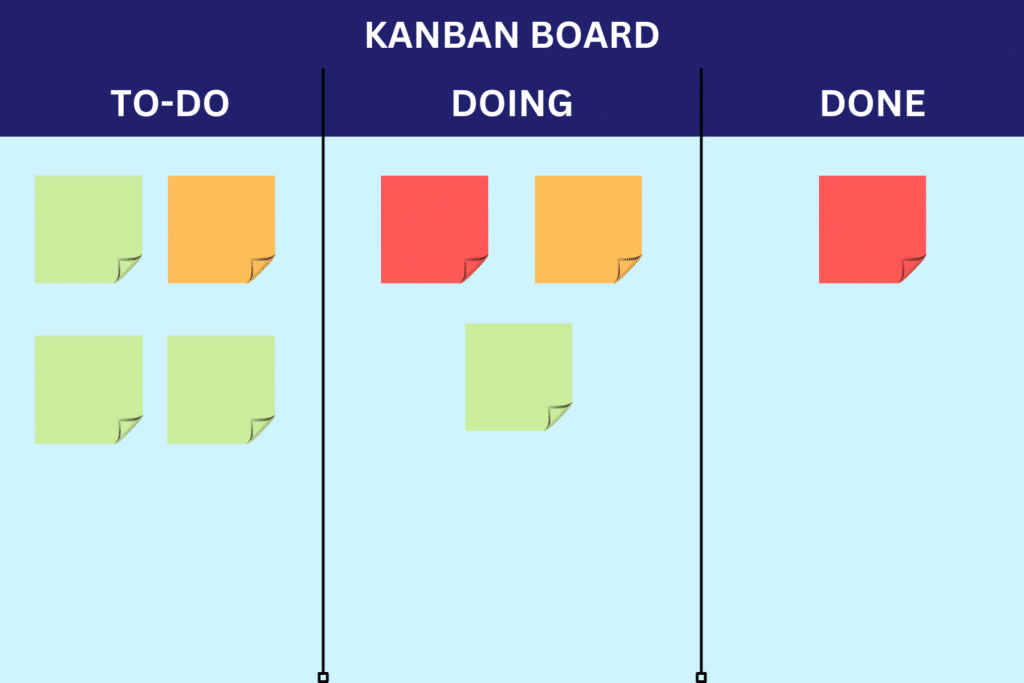

As the name implies, a Kanban board is utilized to visualize a list of work items from “To-Do”, to “Doing”, and to “Completed” status so that team members can view the progress of each task [2, 4]. Basically, with Kanban Board, you increase project transparency among your team by visually clarifying what tasks need to be completed and where tasks are piling up. This visual aid is effective in facilitating resource allocation, streamlining operations, and minimizing inefficiencies [6, 7].

Technically, when you have a work item planned to do, you stick a note of the work item on the “To-Do” section of your board. Then, when you start doing your work item, you move the note to the “Doing” section. And once you have finished the work, you move the note to the “Done” section. And this system repeats with your other work items.

This type of system is why Kanban is often referred to as a flow-based Just-In-Time (JIT) development methodology as it works continuously and work items are sorted based on their priority levels. Those with higher priority will be handled first just in time to be processed, received, or delivered.

PERSONAL KANBAN

While Kanban was initially created to help big teams in factories view and collaborate on their project progress and workflow, individuals can also utilize Kanban to help organize their daily activities. This is what we call the “Personal Kanban”.

Personal Kanban is similar to the basic Kanban system but applies in a personal context [5]. The concept of utilizing Kanban for personal context was initially introduced by Jim Benson and Tonianne DeMaria Barry’s 2011 publication “Personal Kanban: Mapping Work | Navigating Life” which outlines a system for organizing tasks and optimizing productivity [3].

Individuals can use it as a system to manage and organize multiple tasks to promote a sense of balance in their lives and boost productivity [3]. What’s more, it not only aids in monitoring your tasks, progress, and priorities but also visually showcases all of your hard work – fostering a sense of pride in your accomplishments and building internal motivation [12].

Having a Personal Kanban can help one from feeling overwhelmed or stressed due to the workload. A Personal Kanban is simple enough that anyone can use it in their daily lives – be it a professional, employee, intern, student, or family member [14]. All it takes is a need to manage their tasks.

PRINCIPLES OF KANBAN

The Kanban framework operates by following a set of principles, fostering better process management and efficient workflow. These principles were developed as a way to harness the benefits of Kanban to optimize your business process [8].

Below are the fundamental principles of Kanban;

Visualize Workflow

Using a Kanban Board or software, visualize your workflow by detailing your work items (via Kanban cards or written on the board), and your work processes that deliver the product or service [8-9]. A basic Kanban Board consists of three columns; “To-Do”, “Doing”, and “Done”, and Kanban Cards are placed on the board columns depending on their workflow status [10]. Shift your cards from left to right as tasks are completed [9].

Through this visual representation, it can help you and your team see what tasks you need to do and view any bottlenecks that might be piling up [14]. Visualizing workflow is also important as it fuels one’s motivation to accomplish more work when a work item is shifted into the “Done” column.

Limit Work-In-Progress (WIP)

Work-In-Progress (WIP) are the tasks/activities that are still being worked on. In Kanban, it is highly encouraged to set a limit on the number of your WIPs at one time and to complete the current tasks first before starting on a new one – similar to the Pull System [8, 9, 15]. For example, only focusing on completing four tasks in one day. This is to ensure that the workflow runs smoothly across your Kanban Board. However, when setting a limit to your WIPs, it is crucial to truly understand how many tasks you can take up at a time [14]. Start small first and add more if you have too much downtime.

Limiting WIP is important in Kanban to prevent bottlenecks and enhance focus, workflow efficiency, work quality, and work prioritization. Most importantly, it discourages multitasking which can cause work overloads, loss of focus, lack of productivity, bad work quality, and decrease overall work performance [8, 10].

Focus on Flow

Kanban is all about the workflow and, with that, needs to have a displayed movement from one process to the other. Hence, when the first two principles are fulfilled, your workflow should be running smoothly across the Kanban Board. A workflow should be managed by monitoring for any interruptions/bottlenecks and using these as an opportunity for improvement. This includes reevaluating your workflow and adjusting your lead time, cycle time, and WIP limits to match your and your team’s workload capacity [9].

By using the Pull System, it ensures work is ready when the team is ready which helps to minimize the efficiency loss due to waiting and prevent downtime [15]. Additionally, through Kanban Board’s visual representation, it promotes transparency that enables the team to assess the system and make the necessary adjustments to enhance the workflow and minimize task completion time [8]. Improving the flow can help enhance the operations’ efficiency and predictability which, ultimately, improves forecasting and ensures a more reliable commitment to end users.

Continuous Improvement

Part of Kanban is to continuously find room for improvements [2, 8]. While Kanban has proven to be a robust and efficient project management framework, it is not perfect. The effectiveness of your Kanban depends heavily on your team dynamics and workload capacity. The more you understand them and monitor your work progress, the easier for you to do some tinkering on your Kanban system and make improvements for a smoother workflow [9].

The changes do not need to be big. You can start by making small incremental improvements from your observations. Better yet, you and your team can experiment by hypothesizing, testing, and measuring proposed changes and compare them with your current workflow performance. If the results are satisfactory, you can apply these changes to your main Kanban system and continuously monitor workflow performance while looking out for any issues [8]. Continuously improving your Kanban system not only optimizes productivity and your understanding of your work but also ensures that your performance is optimized and customer satisfaction increases.

By following these core principles, you should already get the gist of how to effectively utilize Kanban. Kanban ensures that there is a seamless flow to your team’s project workflow.

However, if you are using a Personal Kanban, focus on the first two key principles to optimize its effectiveness. As explained, Personal Kanban aims to provide individuals with a simple yet powerful system for prioritizing tasks, optimizing productivity, and gaining balance. Unlike complex frameworks, Personal Kanban just needs you to visualize your workflow and set limits on your WIPs so that you can manage your workload and prevent feeling stressed, demotivated, overwhelmed, and burnout.

HOW TO MAKE A KANBAN BOARD?

So, when implementing Kanban for your project or Personal Kanban to manage your daily tasks, you need to make your Kanban Board.

Making one is quite simple. All you need is a whiteboard, markers, a pen, and sticky notes. Once you have all that, you can follow these simple steps below [1, 5, 11];

- Using a marker, make three columns and label each of them as “To-Do”, “Doing”, and “Done”. Based on your usual workflow, you can also customize and add other columns like “Testing”, “Reviewing”, etc.

- Then, take out your sticky notes and pen and write down all of your work items on each sticky note (e.g., Work Item 1 on Sticky Note 1, Work Item 2 on Sticky Note 2, etc). These sticky notes or “Kanban Cards” work as your visual representation of your work item.

- Then, categorize your work items based on the three labeled columns on the whiteboard (e.g., under “To-Do”, put Kanban Card 2: Buy Kanban Board materials and under “Doing”, put Kanban Card 1: Research about Kanban). You can also use coloured sticky notes or label them based on their priority levels.

- Based on your work progress, move each work item from “To-Do” to “Doing” and to “Done”. When you complete a work item, you pull a new one from the To-Do list and this process repeats until all work items are completed.

- And DONE! Customize your Kanban with as many details or colour coding as you need to make your Kanban Board easier to understand for yourself or your team.

Note: Remember to limit your “Doing” list or Work-In-Progress (WIP) to prevent overburdening yourself and your team and to focus only on certain tasks at certain times.

Here’s a simple illustration of how a Kanban Board typically looks like;

HISTORY OF KANBAN

As mentioned, Kanban originated in Japan in the field of manufacturing – specifically the Toyota Production System (TPS) [1, 12]. Taiichi Ohno, a legendary engineer at Toyota, pioneered Kanban in the 1940s as a way to manage their assembly line and empower frontline workers to take ownership of the final product, rather than just their individual tasks [1-2].

On top of that, according to sources, Ohno believed that if teams can visualize the entire process, understand the impact of each of their work, and spot emerging issues through Kanban, productivity can be enhanced and waste reduced [1].

This is proven to be true since Kanban has helped Toyota as its visual scheduling system triggering the logistical chain of production. It facilitated Just-In-Time manufacturing and ensured inventory levels aligned seamlessly with actual demand, optimizing operational efficiency [2, 13, 15]. When supplies were running low, the team dispatched the Kanban card to the warehouse, prompting the release of inventory and the replenishment of materials within the production flow through its pull system [5, 15].

Today, Kanban has become one of the most popular project management frameworks that help teams and individuals – in multiple fields (from Software Development to Sales and Human Resources) and even in their personal lives – efficiently manage projects, deliver tasks, and achieve goals.

KANBAN IN MANUFACTURING/PRODUCTION

For a more complex understanding of how Kanban can be implemented;

In the manufacturing industry, for instance, Kanban is used to help companies eliminate waste, improve efficiency, and reduce lead time, inventory, and cost. As Kanban is a subsystem of Lean manufacturing, it helps in controlling inventory levels, and the production and supply of components [16]. Additionally, Kanban as a pull system allows production at a required rate and controls product and inventory preparation as well as delivery of material (items, parts, and raw materials) only when there is a need – signaled through the use of Kanban cards [17- 19].

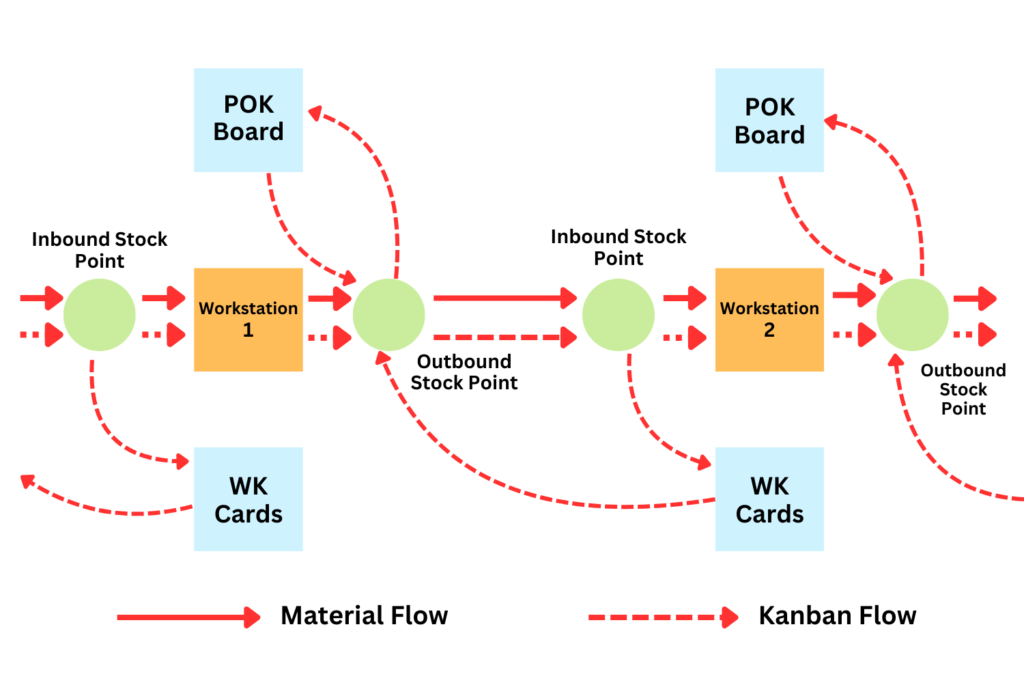

The Kanban card system is mostly used in manufacturing and production. There are two types of Kanban card systems which are the single-card Kanban system and the two-card Kanban system. The single-card Kanban system uses only one Kanban card – the Production Order Kanban (POK) – to trigger upstream production when needed. On the other hand, the two-card Kanban system uses two cards – Withdrawal Kanban (WK) and Production Order Kanban (POK) where the WK card is used to withdraw needed goods from the preceding process while the POK card is used to instruct the preceding process to produce what is needed for replenishment purposes [15].

The 2-card strategy is one where if the shipping department needs products, it sends its Kanban card to the store. The store provides the products and sends its Kanban card to the production line. The production line then begins making more products.

The concept of a Kanban card system in production or manufacturing begins when a material handler retrieves a standard parts container from the outbound stock point with a WK card. This card authorizes the handler and specifies where the parts are needed. Subsequently, the POK card is removed from the container and placed on the POK board before the container is taken away. Production will only start with a POK card, the appropriate incoming parts container, and an available workstation. Once these are ready, the worker retrieves a parts container from the inbound stock point, places the WK card in the workstation’s card hopper, and commences processing the parts. Periodically, a material handler collects WK cards, fetches the required parts, transports them to the workstation, and the process repeats at the next upstream workstation [18]. This system is quite popular as it provides a more efficient, systematic, and organized inventory and production management.

The implementation of a Kanban system is quite beneficial for a company. For instance, Ongkowijoyo et al. [19] highlighted the implementation of a two-card Kanban system to improve the efficiency of the supply chain in the injection molding production line at an Indonesian toy manufacturing company. It was discovered that their push production approach for material preparation had resulted in delays in supplying materials to the production line – resulting in inefficient material distribution within the injection molding department. Hence, a need to implement a pull system through Kanban.

Through the DMAIC framework, the study started its problem identification by reviewing, the current state condition and determining the scope of the Kanban system development involving the company’s material department (material mixing station and regrind station) and the injection molding production line. However, since the machine capabilities calculation shows no delayed problems coming from insufficient regrind machine rate to supply the regrind material needs, a brown paper critique session was conducted to obtain employee feedback and critique.

This was then followed by a root-cause analysis where 47 critiques, gathered from the brown paper critique session, were categorized through a Fishbone Diagram. Results found that the causes of the delay of material supply to the production line came from Manpower (machine and material operator do not notice the material level on the machine), Material (insufficient quantity of material), Machine (no sign in the machine that indicates the low material level), and Method (no schedule about which machine should be served first for regrind process).

With the development of Kanban through a two-card system, materials will only be transported along the factory with the authorization of Kanban cards (WK: Withdrawal Kanban and POK: Production Order Kanban). So, the WK card authorizes the withdrawal of material from the material department to the injection molding production line while the POK card authorizes the preparation of materials. Based on the purchase order, the WK card is sent to the respective Kanban post in either the mixing or regrind station, according to the needs. Then the POK card is sent to the operator handling either the mixing or regrind station who will start preparing the material (based on information on the card). Once the material is prepared, the POK card will be brought back to the Kanban post and the material will be delivered to the injection molding machine along with the WK card. The machine’s material requirements will be indicated visually through a reorder point within the machine’s hopper (material tank).

Once the Kanban system is established, its performance and impact are measured to evaluate its effectiveness. Business process modeling and simulation software are utilized to gauge the Kanban system’s performance. This is achieved by analyzing the time required to produce the same quantity of units under various process flows.

Results have shown to be positive in that the new Kanban system has achieved a 15% improvement in production lead time, 11.1% improvement in production flow rate, and 13.2% improvement in resource utilization – compared to their initial push production system.

BENEFITS OF KANBAN

Now that most of the details of this great framework have been described and ways to create your own Kanban Board have been demonstrated, let’s explore its benefits. From reading the above, you can kind of get the gist of the benefits that Kanban has to offer. So, the below is just a list that summarizes Kanban’s key benefits;

- Increased Visibility of Workflow

- Improve Workflow Tracking & Monitoring

- Enhanced Efficiency & Delivery Speed/Throughput

- Enhanced Project Management Skills in Task Selection & Prioritization

- Streamlined Collaboration

- Enhanced Focus & Alignment to Project Objectives

- Optimized Productivity

- Improved Predictability

- Improved Quality

- Increased Customer Satisfaction

- Foster a Culture of Continuous Improvement

- Adaptable & Customizable Framework (Work & Personal Context)

- Minimizing Bottlenecks

- Minimizing Multitasking & Work Overload

APPLYING KANBAN IN EVERYDAY LIFE

Almost anyone can use Kanban since it is very simple and adaptable to apply in our lives. It is a versatile method that can revolutionize both your work and personal life, helping you achieve greater efficiency, organization, and success in all your endeavors.

Based on the different parts of your life, you can create multiple Kanban Boards to separate your goals and promote work-life balance. For instance, if you are an employee, you can create a “Home” or “Personal” Board and then a “Work” Board whereas if you are a student, you can create a “Home” Board and “University” Board.

At Work:

It is already quite self-explanatory how useful Kanban can be at work. Not only is it a game-changer for managing multiple projects simultaneously, but teams can track progress, prioritize work, and collaborate effectively, even when working remotely. Whether it’s customer service, software development, or article writing, Kanban ensures that everyone stays on the same page and work flows smoothly from start to finish.

It all depends on how you design and categorize your Kanban system. For instance;

Manage multiple projects at once

If you are an employee involved in multiple projects, you can make a swimlane Kanban Board with multiple rows representing the different projects (e.g., 1st Column: Project 1, 2nd Column: Project 2, etc.) and plan out the work items that you need to prioritize according to your “To-Do”, “Doing”, and “Done” columns.

Product Development

If you are involved in a team for product development, your team can use Kanban boards to manage your workflow. For instance, your team can create your Kanban boards with multiple process columns such as from “Backlog”, “Designing”, “Developing”, “Testing”, “Review”, and finally “Launched”.

Customer Service

If you work in customer service, you and your team can create a Kanban Board that can address and follow up with customer inquiries, complaints, requests for support, etc. You can categorize the columns in your Kanban Board based on your usual process to follow. For instance, starting from “New Support Ticket”, “Triaging”. “In Progress”, “Pending Response”, “Follow up”, and finally “Resolved”.

Article Writing

If you are a writer, your Kanban Board can also use multiple columns to show the workflow that you can follow such as from “Topics”, “Research”, “Drafting”, “Editing”, “For Review”, and finally to “Published”.

At Home (Personal):

Now, beyond the office, Kanban also offers invaluable support for organizing personal tasks and projects. By mapping out tasks on a Kanban board, individuals can stay focused, prioritize activities, and make steady progress toward their personal goals. Whether it’s establishing a daily routine and chores with your family to creating a study plan, Kanban empowers individuals to take control of their lives and achieve balance and fulfillment in every aspect.

Study Plan:

Kanban is beneficial for organizing study materials, tracking study sessions, and managing academic deadlines. Students can use Kanban boards to outline study goals, schedule study sessions, and monitor their progress, ensuring effective study habits and academic success.

Event Planning:

Kanban is useful for organizing and managing events, such as parties, gatherings, or celebrations. You can use Kanban boards to outline event planning tasks, assign responsibilities, and coordinate logistics, ensuring that the event runs smoothly and successfully.

Vacation Planning

Kanban can also help us plan vacations by organizing tasks such as booking accommodations, arranging transportation, creating packing lists, and scheduling activities. By visualizing vacation planning tasks on a Kanban board, we can stay organized, track progress, and ensure that all aspects of their trip are taken care of.

Daily Chores

Kanban can help us manage their daily routines and schedules by visualizing daily tasks, appointments, and commitments. By organizing daily tasks on a Kanban board, we can prioritize activities, allocate time effectively, and maintain a productive and balanced daily routine.

RECOMMENDED KANBAN DIGITAL TOOLS

Traditionally, Kanban project management involved planning on a whiteboard or chalkboard. But, with today’s advanced technology, there is a plethora of software that offers a Kanban template that can be used to manage your tasks and projects. Here are some recommendations;

- Jira

- Businessmap (Formerly Kanbanize)

- Trello

- Asana

- Monday

- ClickUp

Project management software enables you to take the Kanban framework’s principles and implement them more efficiently while also adding some additional features. Some useful features are automatic notifications, quick and customizable templates, comment features, and many more to explore! With project management software, you can easily create a virtual board where deliverables can be monitored and progressed.

All in all, you do not have to slave yourself trying to juggle hundreds of things at one time to be successful and risk your happiness. Improving your performance by harnessing the capabilities of Kanban can significantly change your way of life. By faithfully applying Kanban principles, you’ll amplify efficiency and reach your goals with greater ease and effectiveness.

NEED TRAINING?

Then, come and enroll in our Lean Six Sigma training now and learn the methodologies and techniques to increase profitability through waste elimination, quality management, and continuous improvement!

Choose your preferred training mode here; public training, in-house training, and online training.

BE A MEMBER TODAY!

Join us and become a member to receive various membership perks – vouchers, discounts, networking, and more! Visit us at https://sixsigma.org.my/membership/ for more information.

Looking forward to having you onboard!

Follow MBizM Group channel on WhatsApp and get the latest updates on Lean Six Sigma facts and training programmes!

REFERENCES

[1] K. Doll, “What is the Kanban System? the best way to stay productive,” Shortform, https://www.shortform.com/blog/what-is-the-kanban-system/ (accessed Mar. 14, 2024).

[2] Product Marketing Team, “Ways of using Kanban in your daily life,” Jile, https://www.jile.io/blogs/personal-kanban-board-in-daily-life (accessed Mar. 14, 2024).

[3] J. Everitt, “The Complete Guide to Personal Kanban: Wrike,” Blog Wrike, https://www.wrike.com/blog/complete-guide-personal-kanban/ (accessed Mar. 14, 2024).

[4] “Kanban – A brief introduction,” Atlassian, https://www.atlassian.com/agile/kanban (accessed Mar. 14, 2024).

[5] K. Eby, “The Essential Guide to Personal Kanban,” Smartsheet, https://www.smartsheet.com/using-personal-kanban-find-new-job-jumpstart-your-career-or-accomplish-more-your-current-role (accessed Mar. 14, 2024).

[6] Indeed Editorial Team, “What Is a Kanban Board? Definition, Benefits and Tips,” Indeed, https://www.indeed.com/career-advice/career-development/kanban-board (accessed Mar. 14, 2024).

[7] Coursera Staff, “Kanban vs. Scrum: What’s the difference?,” Coursera, https://www.coursera.org/articles/kanban-vs-scrum (accessed Mar. 14, 2024).

[8] M. Simmons, “Kanban Principles & Best Practices explained,” ProjectManager, https://www.projectmanager.com/blog/kanban-principles (accessed Mar. 14, 2024).

[9] S. Buehring, “ The 4 Kanban principles: A visual guide,” Knowledge Train, https://www.knowledgetrain.co.uk/agile/agile-project-management/agile-project-management-course/kanban-principles (accessed Mar. 14, 2024).

[10] “Personal kanban – using Kanban to improve personal productivity,” Nimblework, https://www.nimblework.com/kanban/personal-kanban/ (accessed Mar. 14, 2024).

[11] M. Taffer, “4 simple examples of Kanban in action: How it actually works,” The Digital Project Manager, https://thedigitalprojectmanager.com/projects/pm-methodology/kanban-examples/ (accessed Mar. 14, 2024).

[12] “What is personal Kanban Board and how to use?,” [Full Guide] How to Creating Your Personal Kanban Board, https://boardmix.com/tips/personal-kanban-board/ (accessed Mar. 14, 2024).

[13] Toyota Blog, “Kanban – Toyota Production System Guide,” Toyota UK Magazine, https://mag.toyota.co.uk/kanban-toyota-production-system/ (accessed Mar. 14, 2024).

[14] A. Deshpande, “Using Kanban for your everyday life!…,” LinkedIn, https://www.linkedin.com/pulse/using-kanban-your-everyday-life-csm-istqb-ctal-test-manager-tkp/ (accessed Mar. 15, 2024).

[15] A. Naufal, A. Jaffar, N. Yusoff, and N. Hayati, “Development of kanban system at local manufacturing company in Malaysia–case study,” Procedia Engineering, vol. 41, pp. 1721–1726, 2012. doi:10.1016/j.proeng.2012.07.374

[16] R. Sundar, A. N. Balaji, and R. M. S. Kumar, “A review on lean manufacturing implementation techniques,” Procedia Engineering, vol. 97, pp. 1875–1885, 2014. doi:10.1016/j.proeng.2014.12.341

[17] M. L. Junior and M. G. Filho, “Variations of the kanban system: Literature review and classification,” International Journal of Production Economics, vol. 125, no. 1, pp. 13–21, May 2010. doi:10.1016/j.ijpe.2010.01.009

[18] W. J. Hopp and M. L. Spearman, “To pull or not to pull: What is the question?,” Manufacturing & Service Operations Management, vol. 6, no. 2, pp. 133–148, Apr. 2004.

[19] Y. K. Ongkowijoyo, A. T. Pratama, and T. D. Sofianti, “Supply chain improvement in a local toy manufacturing company by a Kanban System,” Presented at the Proceedings of the 2020 International Conference on Engineering and Information Technology for Sustainable Industry, Sep. 2020. doi:10.1145/3429789.3429851